History of sugarcane in Kenya

Sugarcane cultivation in Kenya began in the early 19th century by the Indian settlers in Kibos. The sugarcane was initially milled by jaggery plants. The establishment of two factories, Miwani in Kisumu County in 1922 and Ramisi in Kwale County 1927, marked the beginning of large scale commercial sugarcane production in the country for extraction of sucrose as the major product. The by-product includes molasses, bagasse and filter cake.

After independence, the Government explicitly expanded its vision of the role and importance of the sugar industry as set out in Sessional Paper No. 10 of 1965 which sought, inter alia, to:

- Accelerate socio-economic development;

- Redress regional economic imbalances;

- Promote indigenous entrepreneurship; and

- Promote foreign investment through joint ventures.

Recognizing the importance of the sector, the Government and the private sector have been involved in the promotion of the industry through direct investments mainly on factories for processing cane and other related infrastructure:

State-owned -Muhoroni (1966), Chemelil (1968), Mumias (1973), Nzoia (1978), South Nyanza (1979),

Privately owned -West Kenya Sugar Company Ltd (1981), Soin Sugar Company Ltd (2006), Kibos Sugar and Allied Industries Ltd (2008), Butali Sugar Mills Ltd (2011), Transmara Sugar Company Ltd (2011), Sukari Industries Ltd (2012), Kwale International Sugar Company Ltd (2014), West Kenya Sugar Company Ltd –Olepito Unit (2017) and Busia Sugar Industry Ltd (2018).

There are several built-up jaggery mills and numerous mobile jaggery units.

The establishment of the factories aimed at: -

- Achieving self-sufficiency in sugar with a surplus for export in a globally competitive market;

- Generating gainful employment and create wealth;

- Supplying raw material for sugar related industries; and

- Promoting economic development in the rural economy and beyond through activities linked to the sugar industry.

Following this investment in capacity expansion, Kenya attained self-sufficiency in sugar production in 1980 and 1981 by producing 401,239 MT against a demand of 299,514 MT in 1980 and 368,970 MT against a demand of 324,054 MT in 1981.

The successful implementation of the expansion program in the earlier years was attributed to:

- The regulatory and manpower development systems that were put in place by the Government;

- Engagement of a Technical Management Agency;

- Facilitation of frequent training of human resource by the then Kenya Sugar Authority and overseas exposures for technical personnel in countries such as Mauritius;

- A competent human resource base with the requisite expertise;

- Selection of high yielding cane varieties and adequate seed quantity. There was synchronized planning between mills requirement and cane supply; and

- Adequate acreage under cane to service the mills.

Currently, there are 15 sugar factories in the country with a combined capacity to process 44,450 Tons of Cane per Day (TCD). Despite these investments, self-sufficiency in sugar has remained elusive over the years as consumption continues to outstrip supply. The deficit is met through importation mainly from the COMESA states.

Social-Economic Importance

- Contributes about 4.1% to the value of agricultural marketed production and 5.9% of all crops marketed value;

- Economic reach: supports over 8 million Kenyans. (Approximately 17% of the entire Kenyan population) depends directly or indirectly on the industry;

- Provides employment to 500,000 workers along the entire value chain.

- Contributes tax revenues to the Exchequer (VAT, Corporate Tax, personal income taxes, cess);

- Main economic activity in Western, Nyanza, parts of Rift Valley and the Coastal region. Farm households and rural businesses depend on the injection of cash derived from sugarcane.

- The establishment, growth and survival of small towns and market places is also dependent on the incomes from the same;

- Contributes to infrastructure development through road construction and maintenance, construction of bridges;

- Led to the development of social amenities such as education, health, sports and recreation facilities;

- Provides raw materials for other industries such as bagasse for power co-generation and molasses for a wide range of industrial products including ethanol which is a key ingredient in the manufacturing of various industrial products such as alcoholic beverages and pharmaceuticals;

- Contributes to national energy needs through Co-generation. Millers are in negotiations with energy stakeholders for better feed in rates.

Sugarcane Growing areas

Currently, Sugarcane is grown in 14 Counties by an estimated 270,000 growers. The fourteen Counties include Bungoma, Kakamega, Busia, Transnzoia, Uasin Gishu, Nandi, Kericho, Kisumu, Siaya, Homabay, Migori, Narok, Kisii and Kwale. These sugarcane growing Counties are broadly categorized into four zones: Nyando, South Nyanza, western and coast. There is potential for sugarcane cultivation in Kerio valley and Tana delta.

Production

Sugarcane is grown at factory owned nucleus estate plantations and individual growers’ farms. Smallholder growers supply over 90% of milled cane.

There were 15 factory catchments with an area of 197,438 (Ha) in 2019. All the sugarcane produced in Kenya is processed into sugar for local consumption.

Agro ecological requirements

Sugarcane grows at low altitudes 10 meters above sea level at the coast to high altitudes up to 2000m above sea level in western Kenya. The crop does well in fertile, deep well drained soils with PH 5 -7.5, free from toxic metals such as Aluminuim (Al) and Manganese (Mn). On average, 1500mm of well distributed rainfall through the growing stages, save for 1 to 2 months prior to harvest to enhance sucrose accumulation will suffice. Sunshine duration of 7 – 9 hours and mean day Temperatures of 24 – 300C are ideal for active growth and ripening.

Sugar production activities

- Primary production activities:

- Sugarcane establishment

- Crop management

- Harvesting and transport

- Sugar processing activities:

The main stages of sugarcane milling are as follows:

- cane reception

- cane preparation

- raw juice extraction

- raw juice Treatment (clarification and filtration)

- evaporation

- syrup clarification

- crystallization

- centrifugation and sugar drying

- packaging and storage.

Production trends

In the last five years, the average area under cane is 200,000 Ha with a production of 5,787,065 tonnes of cane and a yield of 58.07 Tonnes/Hectare.The standard conversion ratio in the sugar factories is 10 tonnes cane to one tonne sugar.

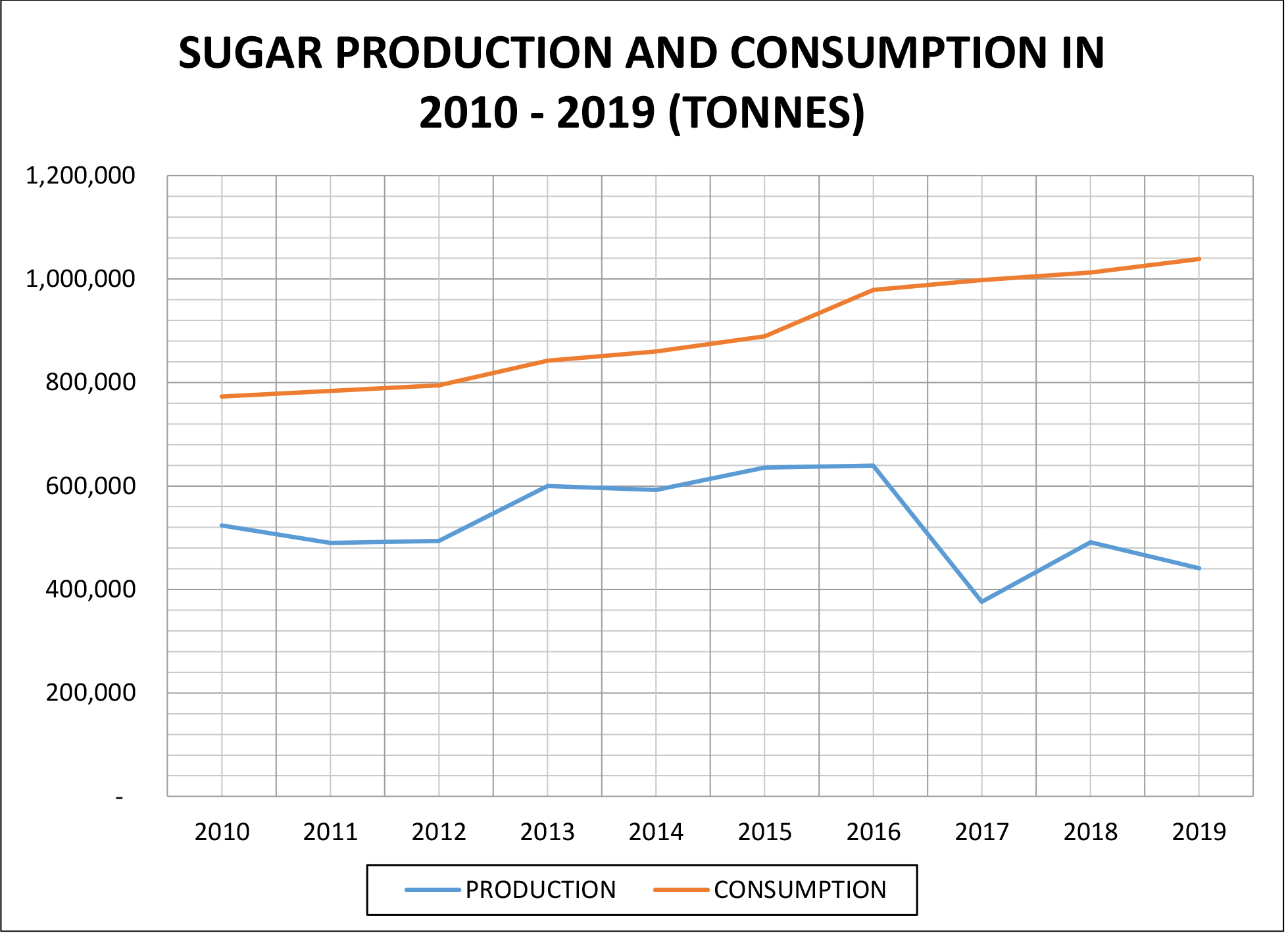

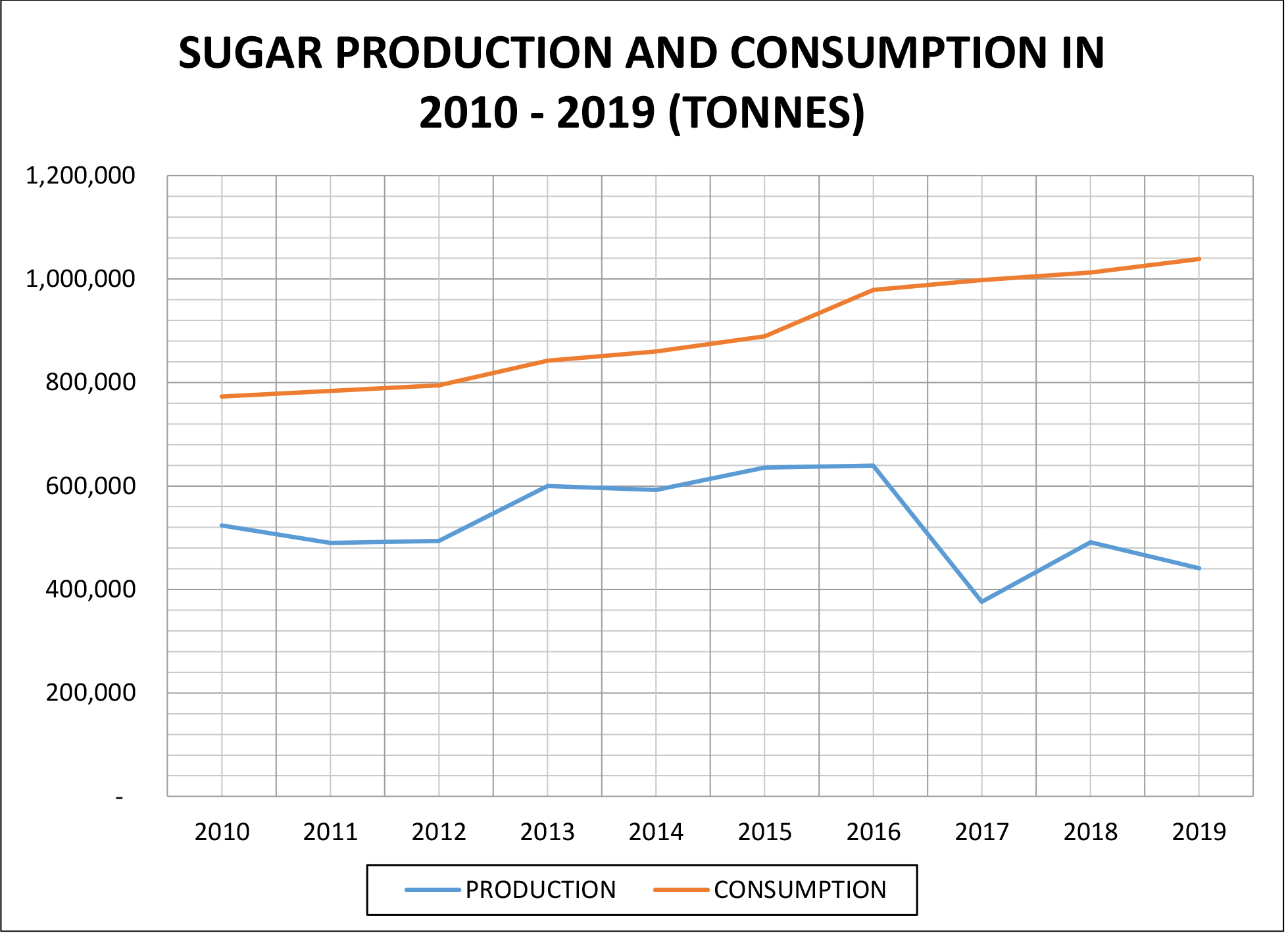

SUGAR PRODUCTION AND CONSUMPTION IN 2010 - 2019 (METRIC TONNES)

|

|

PRODUCTION

|

CONSUMPTION

|

|---|

|

2010

|

523,652

|

772,731

|

|

2011

|

490,210

|

783,660

|

|

2012

|

493,937

|

794,844

|

|

2013

|

600,179

|

841,957

|

|

2014

|

592,668

|

860,084

|

|

2015

|

635,674

|

889,233

|

|

2016

|

639,741

|

978,746

|

|

2017

|

376,111

|

997,944

|

|

2018

|

491,097

|

1,012,399

|

|

2019

|

440,935

|

1,038,717

|

SUGAR PRODUCTION AND CONSUMPTION IN 2010 - 2019 (TONNES)

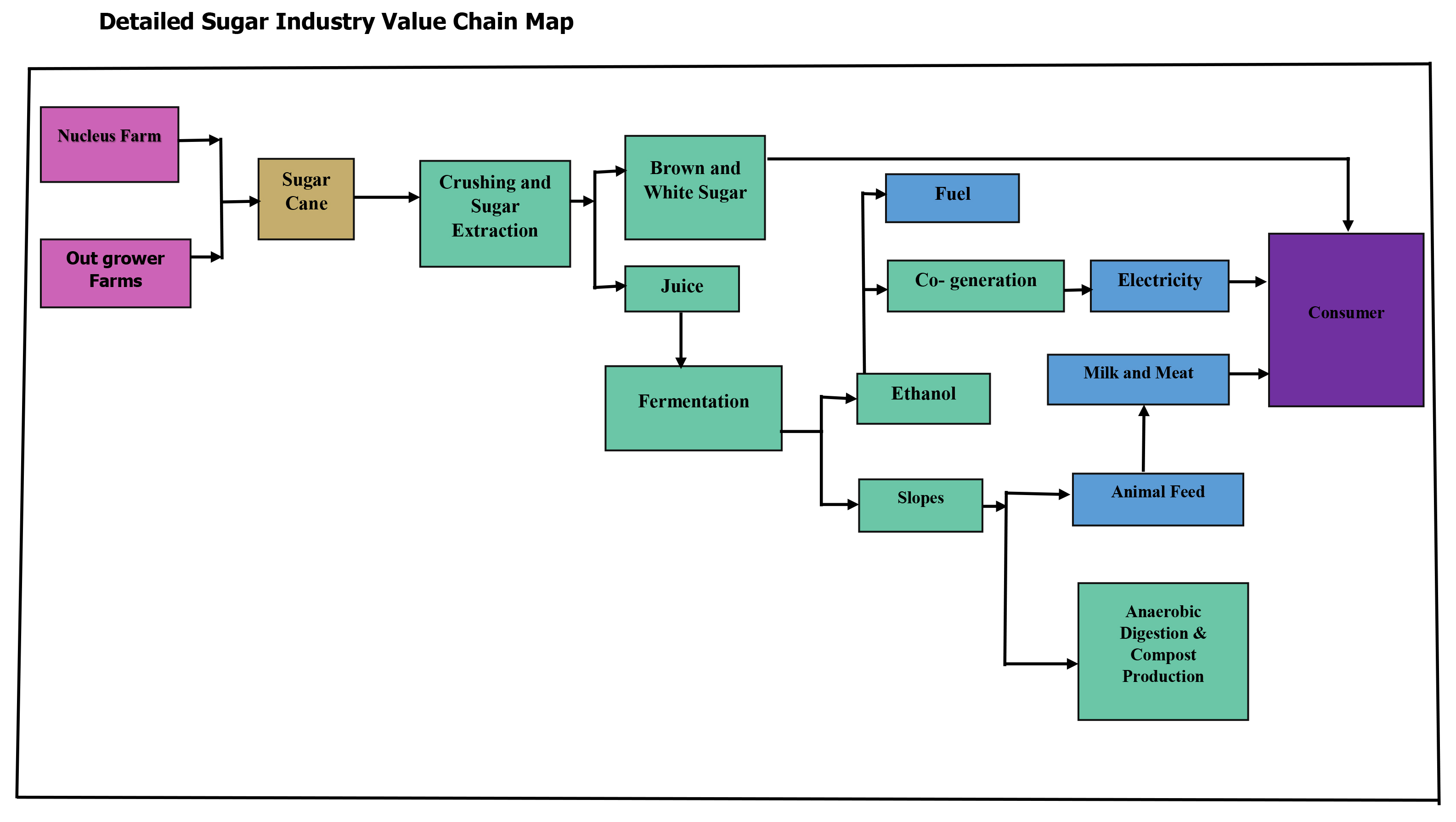

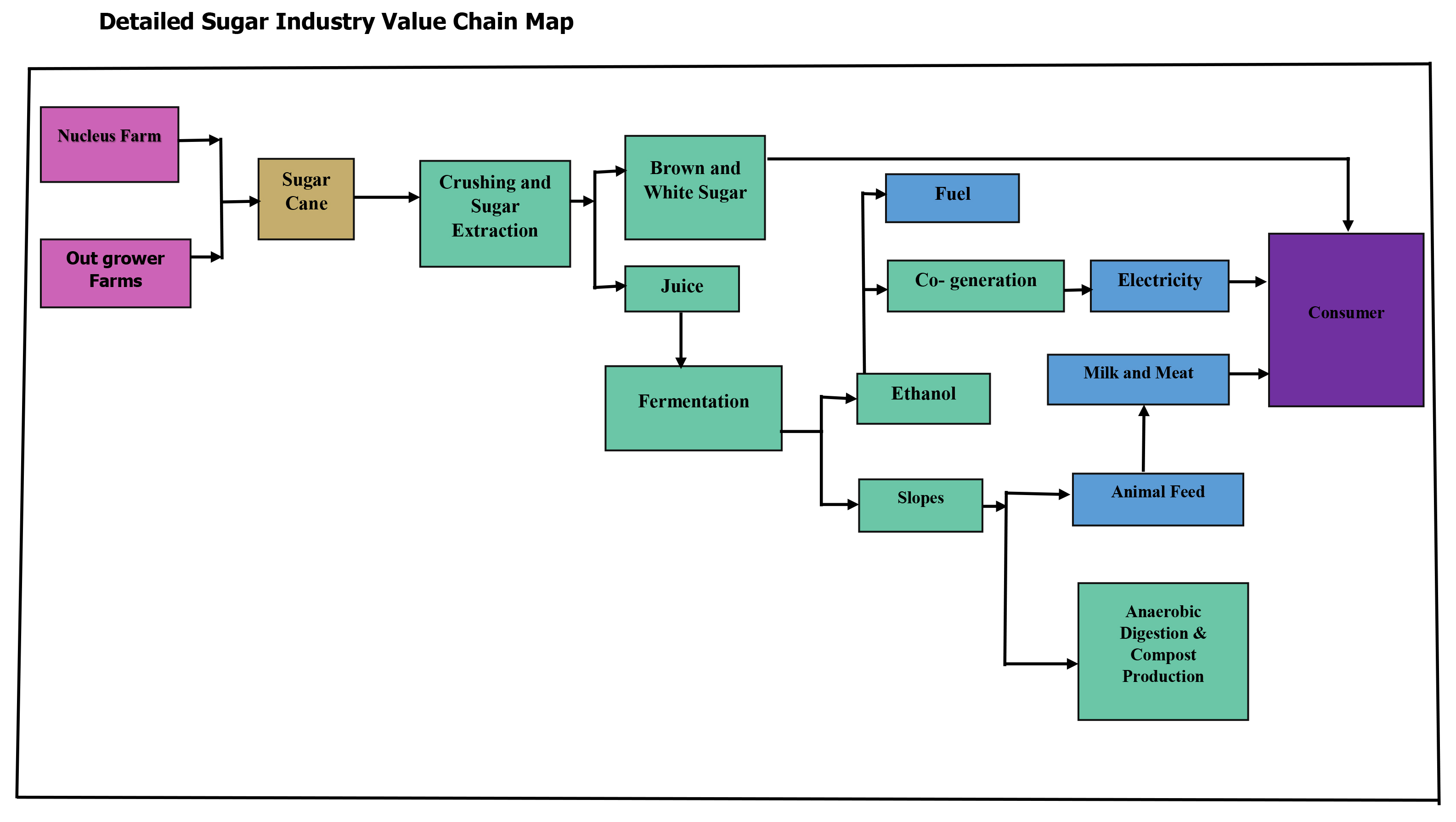

Value Chain Map

Social-Economic Importance

Sugarcane Growing areas

Currently, Sugarcane is grown in 14 Counties by an estimated 270,000 growers. The fourteen Counties include Bungoma, Kakamega, Busia, Transnzoia, Uasin Gishu, Nandi, Kericho, Kisumu, Siaya, Homabay, Migori, Narok, Kisii and Kwale. These sugarcane growing Counties are broadly categorized into four zones: Nyando, South Nyanza, western and coast. There is potential for sugarcane cultivation in Kerio valley and Tana delta.

Production

Sugarcane is grown at factory owned nucleus estate plantations and individual growers’ farms. Smallholder growers supply over 90% of milled cane.

There were 15 factory catchments with an area of 197,438 (Ha) in 2019. All the sugarcane produced in Kenya is processed into sugar for local consumption.

Agro ecological requirements

Sugarcane grows at low altitudes 10 meters above sea level at the coast to high altitudes up to 2000m above sea level in western Kenya. The crop does well in fertile, deep well drained soils with PH 5 -7.5, free from toxic metals such as Aluminuim (Al) and Manganese (Mn). On average, 1500mm of well distributed rainfall through the growing stages, save for 1 to 2 months prior to harvest to enhance sucrose accumulation will suffice. Sunshine duration of 7 – 9 hours and mean day Temperatures of 24 – 300C are ideal for active growth and ripening.

Sugar production activities

The main stages of sugarcane milling are as follows: